As you may have seen I've been designing a

DC DC constant current power supply to drive some LEDs from a 12 Volt supply. The main reason for doing it myself was because most of the drivers I've seen don't have a feature to dim the LEDs by reducing the drive current, they typically drive the LEDs at full power and pulse them on and off to vary the brightness. This can be an issue when used for photography.

I'm getting there slowly, and am close to laying out a PCB, but during my research on LED drivers I found a nice little unit from Mean Well power supplies that allows you to dim LEDs by PWM and Analogue dimming. Granted, they have one of the least reassuring names in the electronics industry, but I like their stuff and have never had an issue with them. (I think I've used their products 4 times before) So I thought I'd get one and see how a professionally designed unit performs. They're cheap enough, you can get one like mine for $20 excluding postage.

![LED Driver LED Driver]() |

| MeanWell LDH-45A-350W LED Driver |

As the unit is potted I can't do much of a teardown, but I did pop the back off and you can see some of the signs of a switch-mode converter. In two locations you can see arrays of vias probably used to dissipate heat into the copper pour from switching elements like diodes or transistors, and small traces coming off large areas most likely indicate parts of the feedback circuit.

![LED Driver PCB LED Driver PCB]() |

| Bottom side of LED driver PCB |

The banner specs are also worth a look. The datasheet is for a family of converters, I have the 350 mA model. I'm happy that they comply to an EMI standard, most cheap stuff from China doesn't worry too much about things like that. Short circuit protection is expected, there's most likely a transistor on the low side of the LED string that's used for PWM control, when an over current is detected this transistor simply shuts off disconnecting the load. Encapsulation is good as well, the unit feels rugged, like it would take some abuse.

![Electrical Specifications Electrical Specifications]() |

| LDH-45 LED Driver Family Specs |

My unit is capable of outputting up to 86 Volts and my panels run at 60 Volts, so that's fine. The voltage input range is also fine, although there is a derating curve in the datasheet. Any Vin lower than 12 Volts won't be able to drive the LEDs at full current.

![Electrical Specifications Electrical Specifications]() |

| LDH-45A-350 specs |

Usage is fairly straight forward, the input voltage is connected to the Vin+ and Vin- wires and the LEDs are connected to the Vout+ and Vout- ones. That's all you need to do if you dan't want to use the dimming features at all, but it will drive the load at full capacity, 350 mA, and my panel is rated for 300mA, so I need to reduce the drive current. For this post I'm not using PWM dimming, I'm just focussing on analogue dimming.

Reducing the drive current is as simple as placing a control voltage across the Analogue DIM and DIM- wires. I assembled a test rig as per the diagram below using an adjustable power supply. The

LED panel I used to test the driver was the one I recently did a review of. Voltages and current were measured at various places around the circuit. You can get my measurements and the datasheet from

here.

![Electrical Circuit Electrical Circuit]() |

| Test setup |

First up I wanted to check the relationship between the analog dimming voltage and the output current. The datasheet gives a graph for this. It's basically a linear relationship between 0.25 to 1.2 Volts.

![Electrical Graph Electrical Graph]() |

| Analogue dimming voltage control from the datasheet |

Remarkably, my results were pretty much spot on. I couldn't go to 100% drive current, but the curve matches well for the tests I performed.

![Electrical Graph Electrical Graph]() |

| Measured analogue dimming voltage control |

I then wanted to test the efficiency of the unit. The datasheet has a graph, presumably at full current, for the maximum efficiency of different number of LEDs with a Vf of 3.15 Volts. In my case that would be 19 LEDs for an efficiency of 0.932

![Efficiency Efficiency]() |

| Efficiency for different LED configurations |

Once again my measurements compared well. Once a decent load was applied I was able to get a consistent efficiency of around 92 percent. Not too shabby at all. This is great, due to its efficiency, it doesn't get noticeably hot, which means no active cooling needed. (YMMV depending on how enclosed it is)

![Electrical graph Electrical graph]() |

| Measured Efficiency for different load currents |

For my own reference I wanted to do some electrical tests. These are all performed with an output current of 300 mA

I wanted to see how noisy the converter was electrically and its operating frequency. The first test I did was to clip the ground lead to the probe tip and hold it over the device, a poor man's EMI probe if you will. You can notice that the device appears to be running at 95 kHz. This is surprising as my design runs at close to 600 kHz, mine could be smaller, but may have more loss. You can also see a few spikes created by switching elements. I could guess what they are, but as I don't know the exact topology used I'd only be guessing.

![Electrical Waveform Electrical Waveform]() |

| Scope probe loop held over the converter |

I then check the input voltage ripple of the power supply, it's in the 50mV range.

![Electrical Waveform Electrical Waveform]() |

| Input voltage ripple |

I then checked the input current. As I didn't have anything specifically set up to do this I clipped the probe leads across the input to a multimeter and used the internal shunt to measure the current. Quick and dirty.

You can see that the input current resembles the charge discharge cycle you'd expect from a boost converter.

![Electrical Waveform Electrical Waveform]() |

| Input current |

As the input current is about 1.67 Amps, the ripple is around 30 mA.

![Electrical Waveform Electrical Waveform]() |

| Input current ripple |

There is also a bit of ringing in the input current, that could be the EMI filter or just inductance from all the test leads I was using.

![Electrical Waveform Electrical Waveform]() |

| Input current ringing |

I measured the output current in a similar way. It was measure to be 300 mA by multimeter.

![Electrical Waveform Electrical Waveform]() |

| Output current |

The spikes in the output current have a magnitude of about 180 mA. Once again, this type of thing may be due to the way I'm measuring things.

![Electrical Waveform Electrical Waveform]() |

| Output current ripple |

You can see ringing in this case as well. L and C as far as the eye can see.

![Electrical Waveform Electrical Waveform]() |

| Output current ringing |

Nothing too exciting here, the output voltage is 60 Volts.

![Electrical Waveform Electrical Waveform]() |

| Output Voltage |

Ripple in the output voltage that looks like this could be down to the ESR of the capacitors in the output filter. As current flows into them, V=IR causes the voltage to rasise slightly, when they discharge the voltage drops. Just speculation, but at 60 Volts, what's a couple hundred milliVolts between friends.

![Electrical Waveform Electrical Waveform]() |

| Output Voltage ripple |

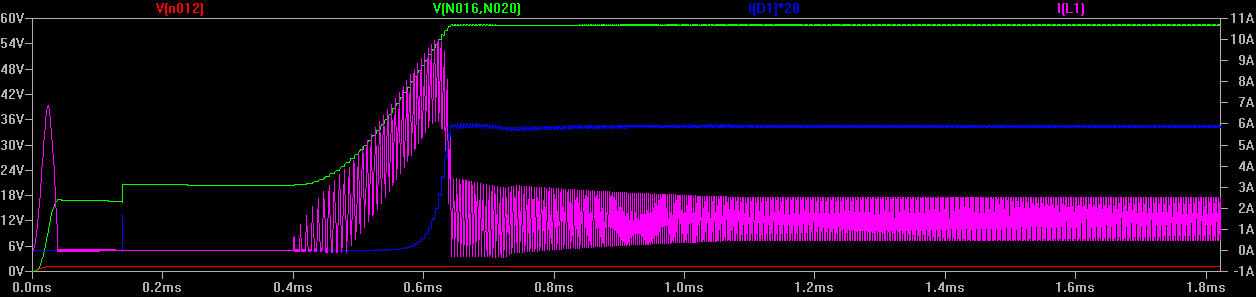

I was very interested in the startup profile as I had a hard time getting mine to behave. From the the point the voltage starts to rise it takes about 25 ms to get to the a stable output voltage. There doesn't appear to be any noticable overshoot. All in all quite nice.

![Electrical Waveform Electrical Waveform]() |

| Startup voltage waveform |

I'm definitely going to use these again. They have all the features I want and are simple to use. I'll need to come up with something to control the dimming inputs, but that shouldn't be too hard. If they're using a chip similar to what I've been using in my design, you should also be able to use the analogue and PWM controls at the same time.

I really didn't want to build multiple units like this, don't get me wrong, I want to learn how to do it, but it's hard to beat a self contained module that sells for $20.